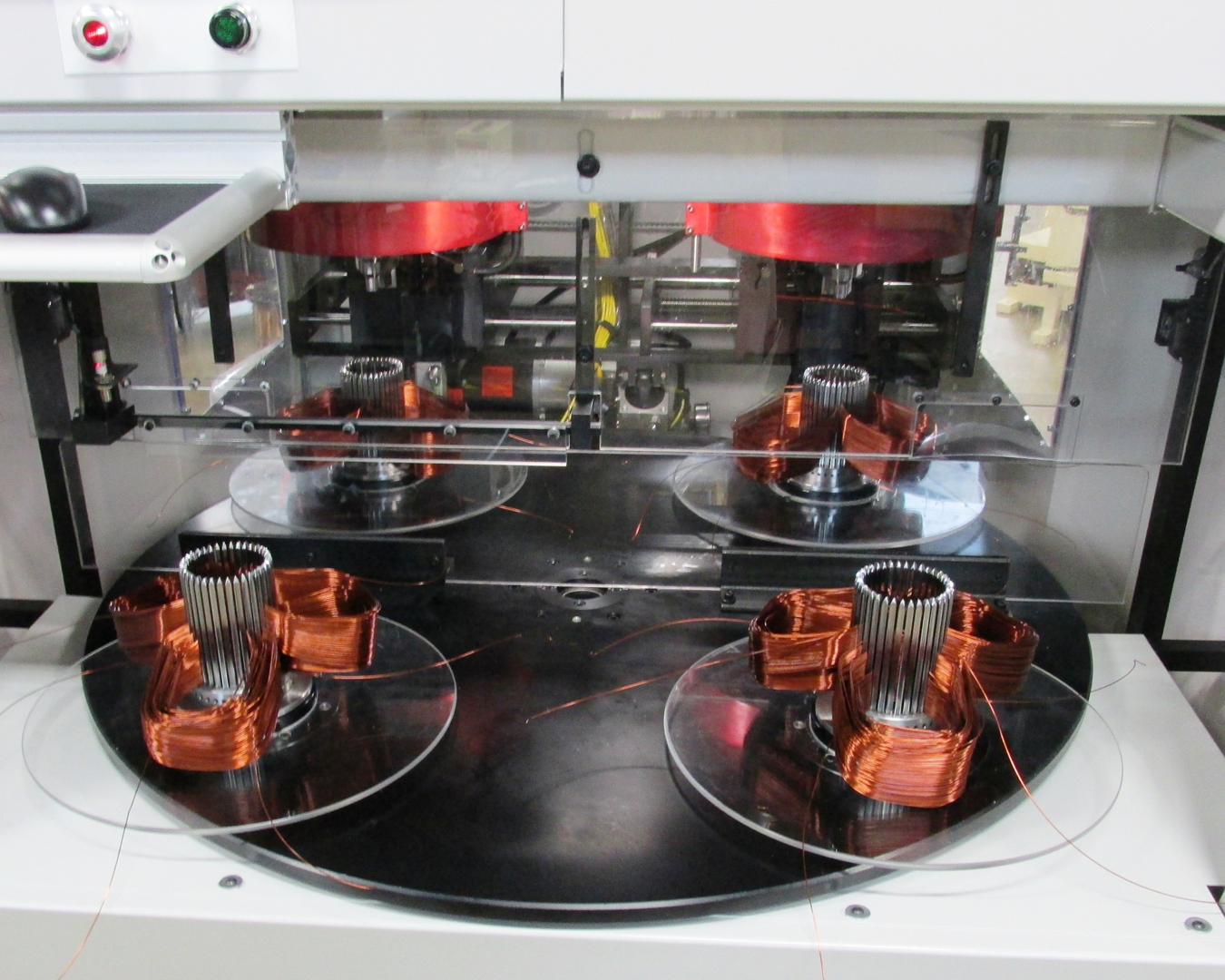

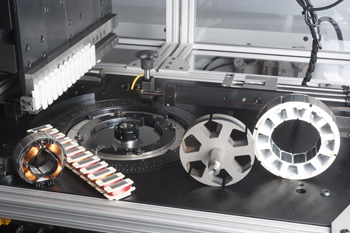

Customized Solutions to Your Winding Challenges

We have years of experience working with customers solving their stator winding and related equipment needs.

We look forward to working with you, to provide a solution to your manufacturing needs.

Latest News

Now Hiring

WGE Equipment Solutions has openings in machine assembly and mechanical engineering. These positions are full-time with excellent pay, health insurance, 401K with company match, holidays, and PTO. Please contact email us at sales@wge-es.com

New Location

NEW LOCATION OPEN, we are please to announce the opening of our Southwest office in Edinburg, Texas. Be on the lookout for more information on this location coming soon.

Industries Served

WGE supplies parts for many different industries, including the following:

Automotive

Electric Vehicle

HVAC

Appliance

Aerospace

Marine

Pump

Power Generation

Get in touch with us today so we can help you with your next project.